Metal Detector - CW

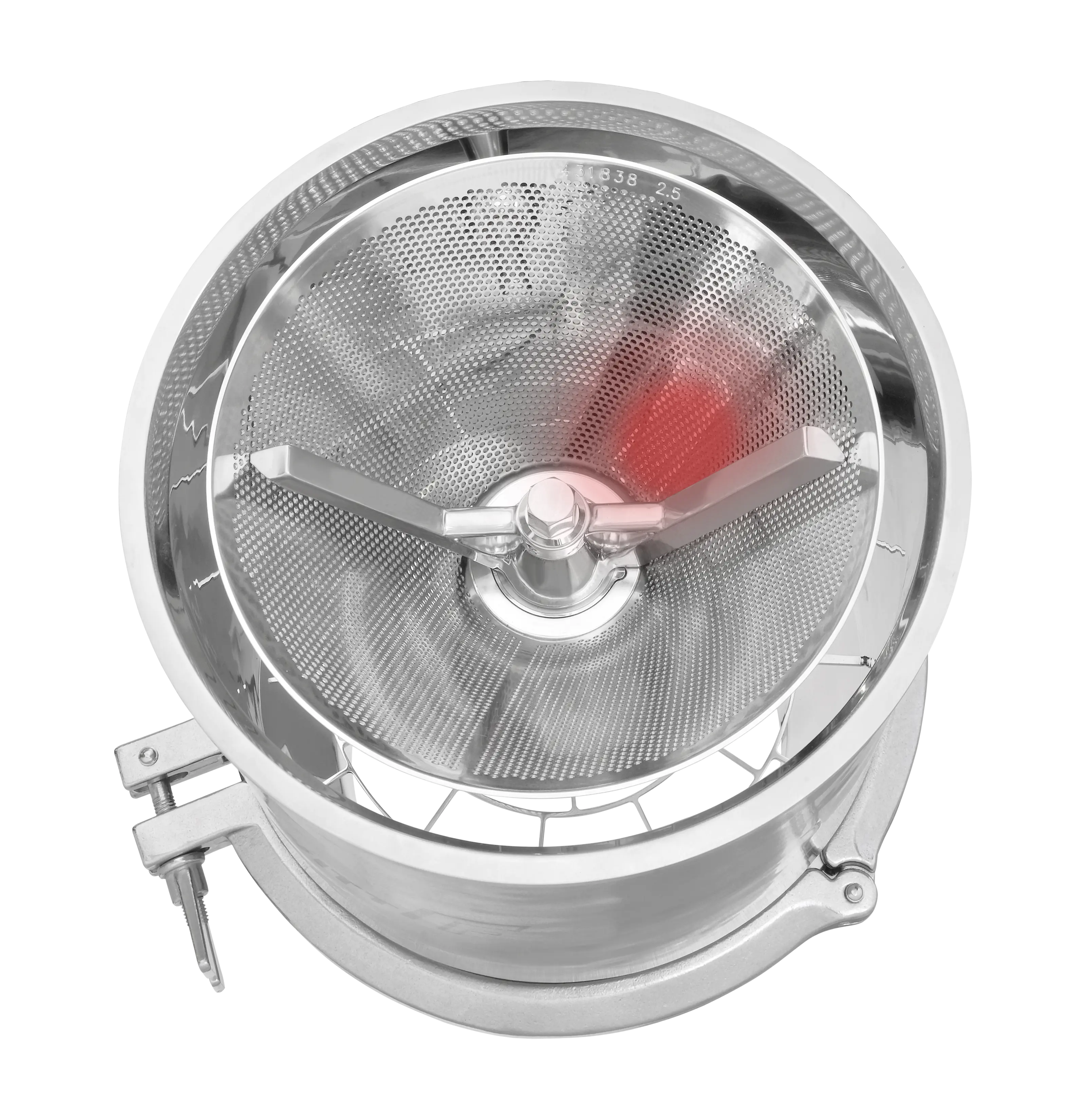

Frewitt Metal Detector - CW

The Frewitt Metal Detector (FMD) is an option that continuously monitors the electrical isolation between the conical sieve and the rotor. This option allows machines to shut down the process in case of any contact between sieve and rotor.

System features:

• Detects any contact between sieve and rotor

• Detects any damage of the sieve surface that may have occurred during its manipulation prior to installation

• Detects metallic foreign bodies between the sieve and rotor

• Detects missing sieve

• Available on Frewitt ConiWitt mills

• Ensures continuous measurement throughout the milling process

This latest innovation reinforces Frewitt’s Total Care Concept, providing safety for the operator, the process and the equipment.

FREWITT : YOUR IDEAL CHOICE

1. Innovative solution to remove risk of process disruption & product loss

2. Helps validate your FDA Audit

3. Can be retrofitted into your existing machines

4. Prolongs the lifespan of the machine and tools by avoiding damage and wear

5. Developed in compliance with the Frewitt Total Care Concept

TECHNICAL SPECIFICATIONS:

Materials:

AISI 316/316L - Ra ≤ 0.8 μm Interior

AISI 304/304L - Ra ≤ 1.4 μm Exterior

IMPLEMENTATIONS:

Standard:

• Foreign metallic body recognition

• Sieve deformation recognition

• Automatic stopping

• Fully integrated into the machine’s control system

Optional:

• WIP

• ATEX

| Contact | +41 (0) 26 460 74 00 |

| sales@frewitt.com |