High-performance pin mill

The PMV-320 Pin Mill enables users to achieve unprecedented performance while removing all risks encountered during milling. Frewitt proposes a new Gold-Standard in terms of safetyfor the user: low stable process temperature preserving API-properties, consistent PSD and the elimination of explosion risk in the smallest possible footprint. (PATENT PROTECTED)

USER BENEFITS:

Competitors require several footprints, Frewitt needs only one single in-line platform.

Unique high impact Pin Mill, delivering a PSD range down to D 90 < 6μm

Throughput up to 1000kg per hour

Compatible for 0/20 ATEX – removal of traditional zone

risks due to the process on the vacuum

Process can be easily contained up to OEB 5

Elimination of noise

Extremely low process temperature elevation

Less product retention than competing technologies

Lowest consumables requirement for this type of process in the market

Compact assembly for easy in-line integration

Adaptable to mezzanine or multi-floor executions

Scalable to Frewitt Lab Scale / Pilot Scale Pin Mill systems

Best cost / value ratio in the market

PHARMACEUTICAL

BATTERY

CHEMICAL

FOOD

Down to D 90 < 6 μm

50–1000 Kg/h

-20°C to +60°C

Ultra high speed

| Length | 3000 mm |

| Width | 3000 mm |

| Height | 5000 mm |

| Weight | 2500 kg |

Exterior

AISI-304/304L - Ra≤3.2 μm

Interior

AISI-316/316L - Ra≤0.8 μm

In product contact, certified by FDA

EPDM/PTFE/Silicone

High-performance pin mill

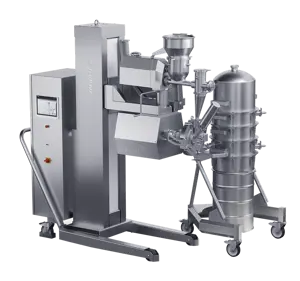

High performance pin mill with cryogenic module

High performance pin mill

High performance pin mill

High performance pin mill with cryogenic module