Your Battery Solution Provider

At Frewitt, we are at the forefront in the development of anode and cathode processes, as well as the manufacturing of customized premium quality mills and installations.

From processing your raw materials to recycling them, Frewitt offers a complete solution for all your battery cell production.

WHY CHOOSE FREWITT?

- We offer complete, adaptable solutions, customized to your requirements

- Designed to ensure safety of the operator, and the process

- Optimized investment with anticipation of your future needs

- Reliable and designed for long term operation

- Machines developed in compliance with the requirements "Frewitt cares about you"

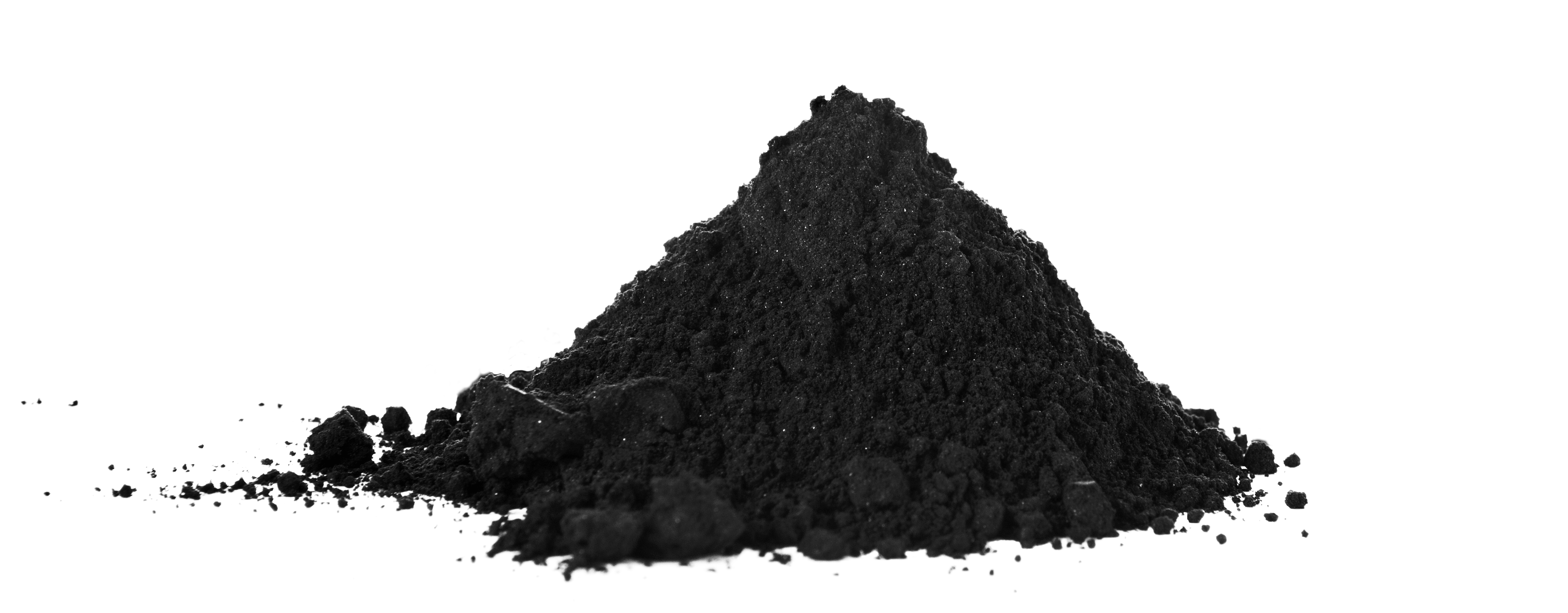

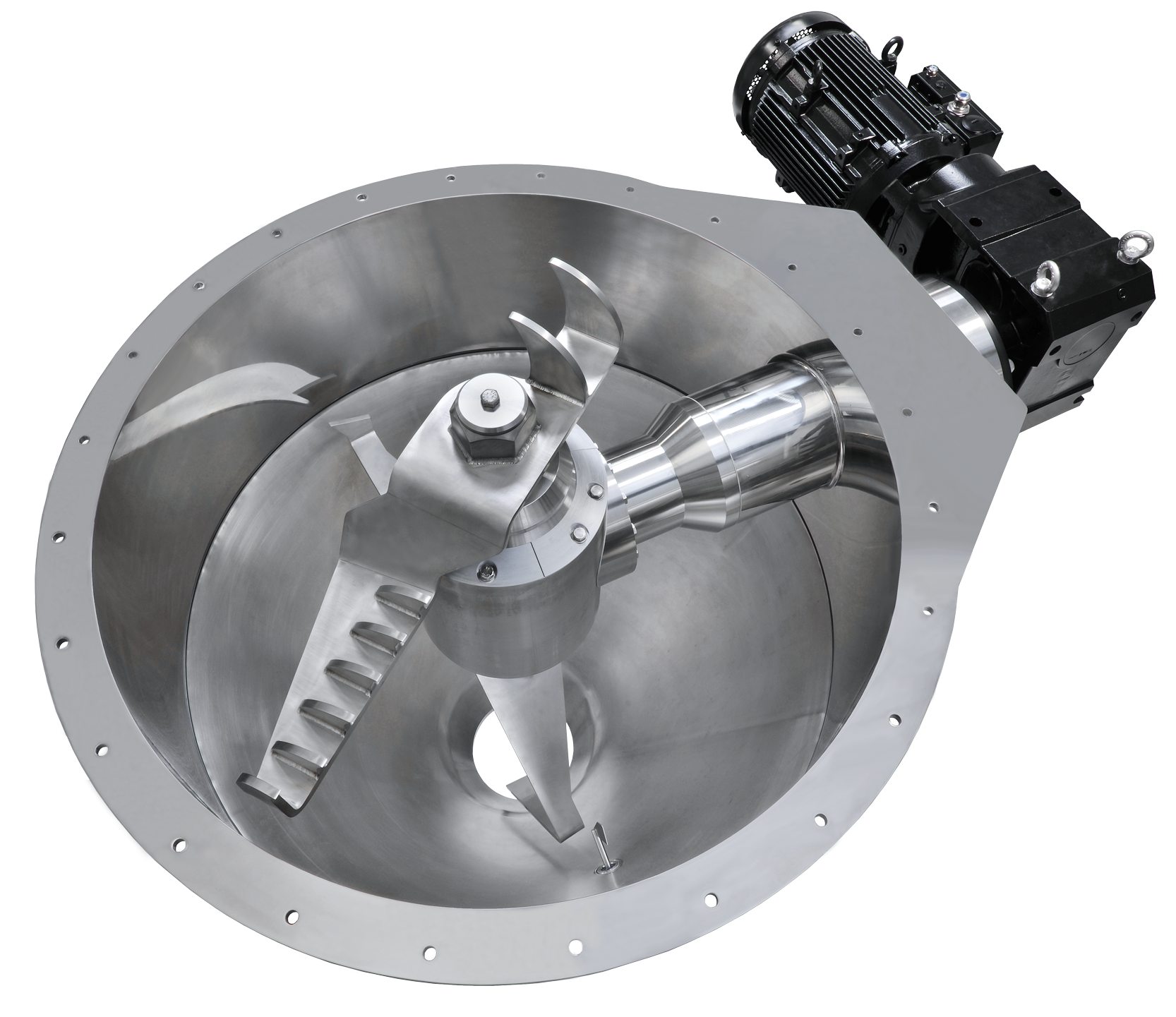

MILLING

Oriented towards the present and future needs of its customers, as well as the anticipation of future trends in the battery industry, Frewitt places its first priority on providing optimal process solutions and thereafter delivering cutting-edge milling solutions, homogenizing, deagglomerating, conveying, handling, dosing and filling systems for powders, granulates and suspensions of every type.

MICRONIZATION

The PMV-320 Pin Mill enables users to achieve unprecedented performance while removing all risks encountered during milling. Frewitt proposes a new Gold-Standard in terms of safety for the user: low stable process temperature preserving API properties, consistent PSD and the elimination of noise and explosion risk in the smallest possible footprint.

DOSING

Our dosing equipment ensures that your product is incorporated into your process in the correct proportions.

CRUSHING

The FlexMill Crusher CC-2 is a solution provider for line blockages during production due to hard, large blocks. Guaranteed to optimize your production time and increase the quality of grinding, it is a unique solution on the market with a crushing zone that covers the entire discharge surface. It is available as a module or a stand-alone machine and is compatible with all Frewitt machines.

SAMPLING

The ProFi-Sample is an innovative sampling device. Its design and development is based on decades of Frewitt know-how. The sampling device is also suitable for operation in a vacuum environment. In addition, the ProFi-Sample’s innovative design allows for complete inertization if required. A notable improvement that Frewitt offers over its competitors is the addition of a hammer dispositive integrated into the spoon, ensuring all of the product always falls off of the spoon even if it is soft or elastic. The ProFi-Sample is available in ATEX 1GD version.

HANDLING WITH IBC

Frewitt provides complete installation including lifter and IBC. We adapt to any customer's physical plant while keeping performance at the forefront of our priorities.

TANK EXTRACTION

The ProFi-Extract can be used to discharge powder and solids from a silo or large tank in order to achieve the desired flow behavior.

CONTAINMENT

Our many years of experience in the pharmaceutical industry have equipped us with extremely high standards when it comes to our products: we produce top-quality stainless steel machinery which guarantees a perfectly contained process and zero risk of product contamination.

PROFI-OEB

For high containment powder handling, dosing and milling. Frewitt offers cone valve solutions for charging and discharging products into IBCs or other equipment while maintaining containment.

RECYCLING

Frewitt is your go-to partner for specialized recycling solutions tailored to your unique demands. Our expert team excels in engineering and manufacturing innovative equipment for the most complex materials like graphite rods, batteries, amorphous polymers, cytotoxic drugs. We provide an entire range of industrial crusher granulators, micronizers and processing systems that can easily reduce large bulk-solid blocks to powder in seconds.

CHARGE, DISCHARGE & CONVEYING

Frewitt can deliver a complete system with motorized roll conveyor with the integration of a contained discharge cone valve. Full automation of the system can be handled by our technical experts.

IBC

Frewitt provides all types and sizes of IBC custom-made as per customers’ requirements.

INSTALLATION PACKAGES

Our installations can include any of the following options while maintaining performance and high-quality:

-

Up to OEB 5 Installation with SMEPAC certification

-

WIP and CIP options

-

SIP with Sterility Assurance and PED 2014/68/EU certification

-

ATEX: Inside 1GD / Outside 2GD

-

Inside: Complete N2 and O2 control

-

Exhaust filter system ProFi-Clean

-

Second safety filter

-

Crusher

-

All milling possibilities

-

Cooling system

-

Conveying system with N2 station

-

Product sampler

-

Dosing device

-

Liner system

-

Welding tong

-

High scale dosing precision

-

Active grounding system

-

Automatization (Siemens, Allen Bradley, CFR 21 Part 11)